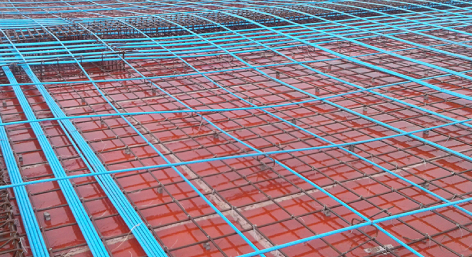

post tension slab

Post tension slab which also call as PT Slab is the pre-compressed slab with the help of LRCP Wire and Anchorage System. This types of slabs are use in commercial, residential, Multi level parking, Auditorium hall etc.

It is a slab with ducts for reinforcement and is made of LRPC Strand. Once the concrete has cured and before the scaffolding is removed, the wires must be tightened by pulling them. This causes the slab to curve upwards, causing all of the concrete to act in compression across the slab. It is commonly referred to as post-stressed concrete.

There are two types of post tension slab

Bonded Post Tension Slab

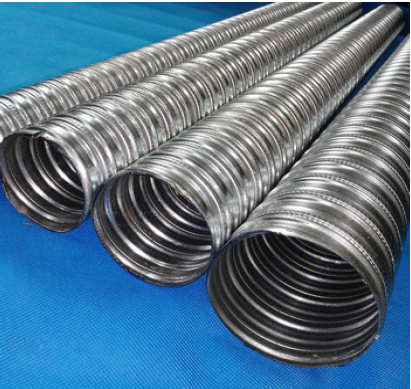

In Bonded Post tension system multiple strand system is used. All the strand is passed through corrugated duct which is made up of either GI Steel or HDPE Material. Than strand is stressed and locked with the help of end anchorage system. Last step is to do grouting operation which fill space between strand and inner side of duct. Bonded post tension system is more popular in European and Asian Countries.

Unbonded Post Tension Slab

In Unbonded Post Tension System single strand system is used. There is no grouting operation needed and strand is free to move. In unbonded post tension system different kind of strand is used in which strand is coated with petroleum grease and top of which plastic sleeve is there through which strand is passed. In this system strand is free to move even after slab casting. Unbonded Post Tension System is more popular in American Countries.

Prestressed concrete is the concrete in which compressive force has been applied to the concrete permanently with the help of HT Wire or Tendons to get superior strength in structure.

Anchoring is the process in which concrete is compressed with the help of LRPC Strands and Post tension system (Anchorage system). Which increase tensile load carrying capacity of the concrete.

There are mainly two types 1)Pretension Concrete 2)Post tensioning concrete

Steel cables in the form of wires or strands are tensioned between end-anchorages and concrete elements cast all around tendons in this technique. When the concrete has cured sufficiently, the end-anchorages are removed, and the compressive force is transmitted to the concrete via the steel-concrete bonding. The tendons' projecting ends are then chopped away to create the completed concrete part.

Because huge anchorages are required to secure all of the tendons, and numerous members may be cast along the same set of tendons, this approach is suitable for factory production. It is critical to ensure that the tendon is free to travel along the prestressing bed otherwise, when the end-anchorages are released, unwanted tensile stresses may be created in concrete.

In this arrangement, prestress force is produced by jacking steel tendons against an already cast concrete part. This procedure is used for nearly all in-situ prestressing. Tendons are routed through steel ducts cast in to the concrete or in rare situations duct travel outside the concrete part. Once the tendons have been fully tensioned, the jacking force is distributed to the concrete through unique built-in anchorages. There are several types of anchorages. In post-tensioned, prestress force is often generated by several individual wires or strands combined into huge tendons and fastened to the same anchorage.

The area between the tendon and the duct in most post-tensioned concrete applications is filled with cement grout. This not only protects the tendons but also increases the member's ultimate strength capability. One benefit of post-tensioning over pretensioning is that tensioning may be done in phases, for all or parts of the tendons in a member. This is effective when the load is applied in discrete steps.

A key difference between pretensioned and posttensioned systems is the ease with which curved tendons may be included in the latter. While the concrete is being pumped around the flexible ducts, they can be held in a curved shape . There are a lot good benefits of having bent tendons . It would be quite difficult to arrange for a curved tendon with pretensioned members.

All the advantage of prestressed concrete are mentioned below.

- Concrete member thicknesses are being reduced.

- The use of rebar in floor components is decreased by 50% .

- Reduction in dead weight will minimize use of concrete and steel which untimely save cost. Height of building will be reduce due to lesser slab thickness.

- Quick Construction of building

- Reduce Deflection

- Reduce Vibration

- Wider spans and less columns provide more flexibility in floor layouts in office/residential buildings.

There are mainly six component with the help of which post tension slab is made.

- Concrete:- Concrete is mixture of Cement, Water, Aggregate like sand, rock and gravel.

- Steel Bar:- Steel bar also known as TMT Bar which is used in post tension slab.

- LRPC Strands (PC Wire or Strand)(LRCP Strands):- PC Wire or Strand, also known as prestressed concrete steel strand, is a twisted steel cable made of high tensile steel wires that have been stress-relieved for use in prestressed concrete structure. It’s available in various size like 15.2 mm, 12.7 mm, 9.5 mm, 5 mm, 4 mm, 3 mm, 2 mm. PC Wire or Strand industrial name is LRCP Strand. LRPC Strands Manufacture in india are Usha martin, TATA Steel, DP Wire, Katariya Steel, MIKI Wire

- Anchorage System or Post tensioning system:- Function of anchorage system or Post tensioning system is to transfer prestressing force from tendon to the concrete. It’s a medium of prestressing force transfer. We at TBEEX PRESTRESSED CONCRETE EQUIPMENTS LLP manufacturing all king of anchorage system (Post tensioning system) having truly competitive rates and supreme quality. All the Post tensioning system manufacturing is pass through our rigid quality assurance system which lead us to 0 defects in our product. For more details you can see our product section and contact us on +91 8200431097 Mobile Number.

- Sheathing Duct:- Mainly two types of sheathing duct is used in post tension construction 1) GI Corrugated Sheathing Duct 2) HDPE Corrugated Sheathing Duct. We at TBEEX Making all the size of GI Sheathing Duct. For more details and rates you can contact us on +91 8200431097

- Grouting Mixture:- Grouting is the mixture of only cement and water in proper proportion.

Post tension slab rates are given in term of per meter of pc wire used in post tension slab. For example if post tension slab rate given by PT contractor is 150 rs per meter and total 2000 m pc strand is used in building construction total cost of post tension service will be 150*2000=300000. Some time rates are also given In term of per kg of pc strand used. Rate of post tension service is vary due to fluctuation in steel price and generally rates are fall in the range of 150-200 Rs per meter.